The Problem: Cracked, Blistered, or Failing Garage Floors

In Western Colorado, many homeowners are shocked when their garage flooring begins to deteriorate just a year or two after installation. What starts as a few blisters or discoloration patches often grows into full-blown peeling, cracking, or flaking. The problem becomes even worse after a snowy winter or wet spring.

The damage might look like surface wear—but it’s almost always coming from below.

The Cause: Moisture-Vapor Transmission in Freeze-Thaw Conditions

Concrete is a porous material that absorbs moisture from the surrounding environment. And in areas like Grand Junction—where mountain runoff, irrigation, and groundwater levels vary—moisture-vapor transmission (MVT) is a persistent issue.

MVT allows water vapor to rise through the concrete slab. If the slab isn’t sealed with a true vapor barrier, that moisture can build up directly beneath the coating—leading to delamination, bubbling, or staining.

In colder climates like Western Colorado, vapor pressure within the slab may also contribute to freeze-thaw stress, which can lead to cracking over time. While no coating can stop internal slab movement entirely, GFC Western Colorado’s 2-day installation system helps prevent surface damage and coating failure by blocking vapor at the source.

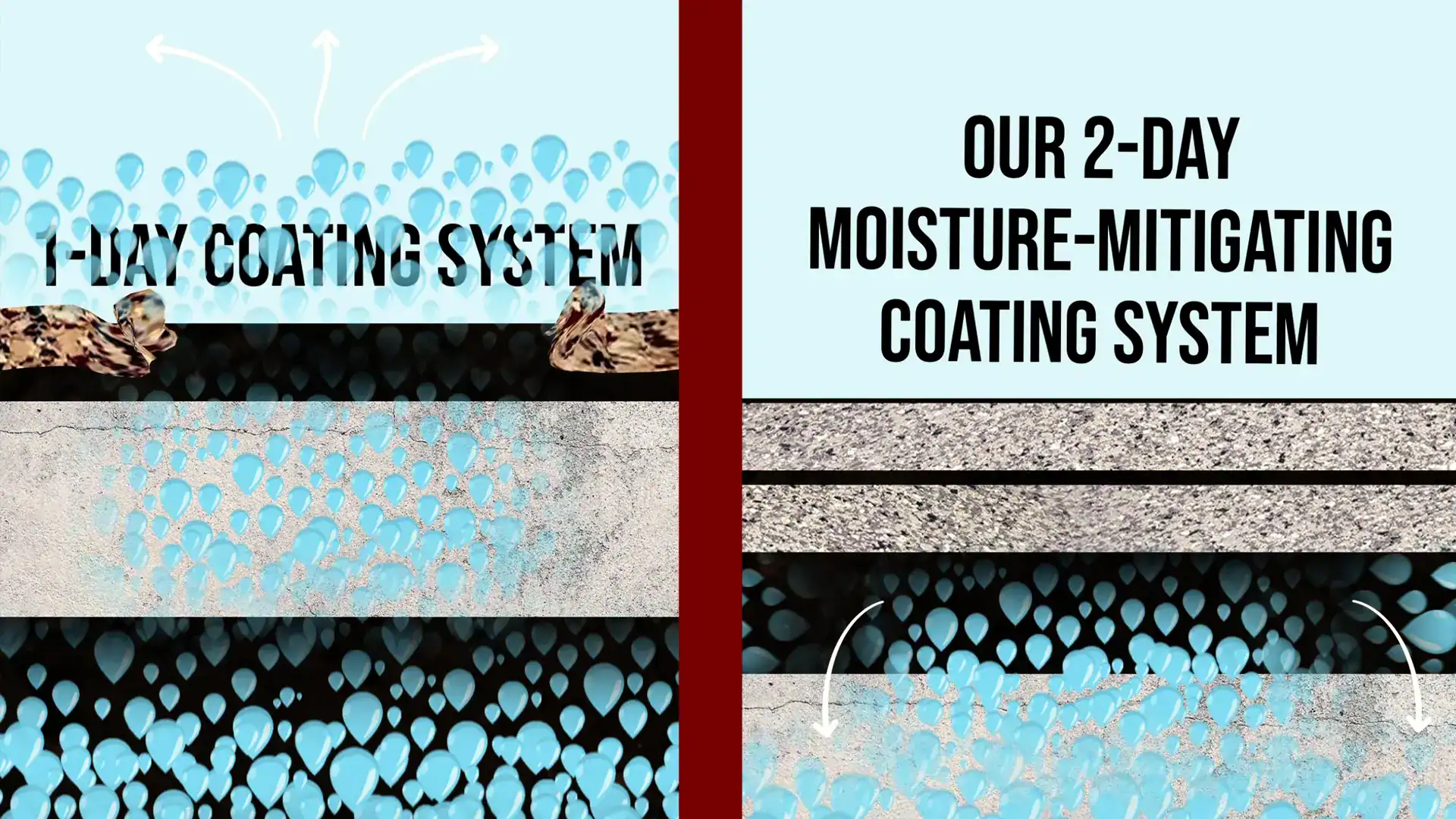

MVT is a serious risk in a region where winter and early spring freeze-thaw cycles are common. Unfortunately, 1-day garage flooring systems are simply not built to handle it. Most 1-day systems rely on polyurea or polyaspartic coatings for both the direct-to-concrete base coat and single top coat. As superb as they are as clear top coats, they’re lousy base coats. Polyurea-polyaspartics, especially in the presence of moisture, cure extremely fast. So fast (well under 1 hour), that they fail to deeply penetrate the concrete…there’s simply insufficient time. In addition, they only go down thinly. So the wafer-thin, poorly penetrating base coat offers no real vapor barrier. The result: beautiful floors that fail early because of trapped moisture pressure.

The Solution: Our 2-Day System Built for the Colorado Climate

Garage Floor Coating Western Colorado installs a 2-day garage flooring system—a moisture-fighting, freeze-resistant solution made for local conditions. The foundation of the system is a 100%-solids, moisture-mitigating epoxy base coat, which slowly soaks deep into the slab, curing overnight, into a vapor-blocking layer. While still “wet”, the selected flake blend is broadcast into this base coat.

On day 2, we return to apply two 100%-solids polyaspartic topcoats…not just one! These dual coats provide extreme UV, stain, chemical and impact resistance—ideal for active garages in high-altitude environments.

Why it works in Western Colorado:

- Epoxy base coat = true moisture mitigation

- Slower cure time = full bonding and freeze-thaw durability

- Dual 100%-solids polyaspartic topcoats = long-term surface protection

Get Garage Flooring That’s Ready for Mountain Conditions

The challenges of Western Colorado require more than a fast fix. GFC Western Colorado’s 2-day system protects your garage from the moisture hiding beneath your slab—and the freeze cycles that follow.

Contact us today to schedule a free estimate and invest in garage flooring built for the long haul.